REQUEST A QUOTE

Request a quote – send us your drawings and application details today. You’re the expert in what you need, and we’re here to get it done for you to your exact specifications.

GET A CUSTOMIZED PLAN

We’ll review them and send you a quote quickly – no waiting while overhead costs spiral. You’ll get a comprehensive quote and an accurate lead time.

FAST TURNAROUND

Questech can offer quick-turn prototypes and handle large volume orders. We pride ourselves on high quality standards at market driven prices.

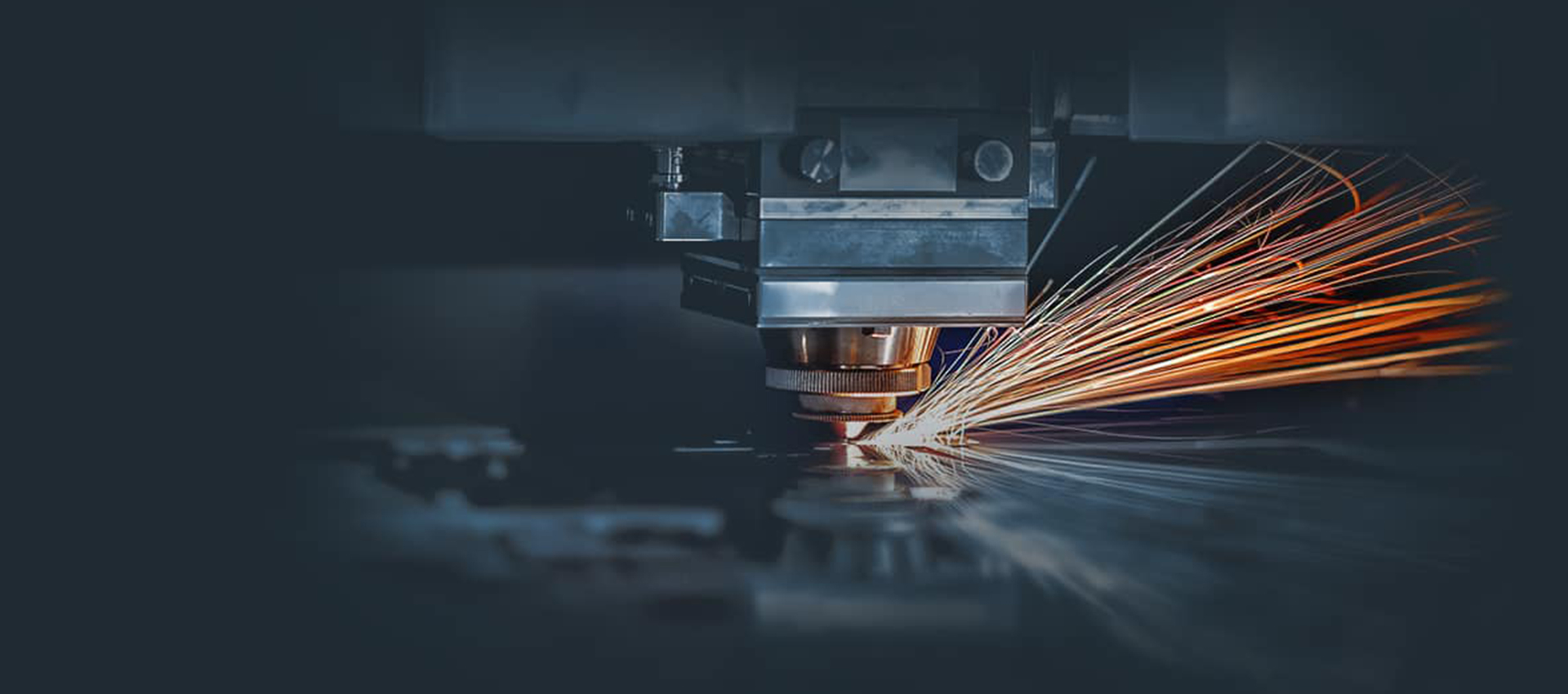

High-Quality Machining in Record Time

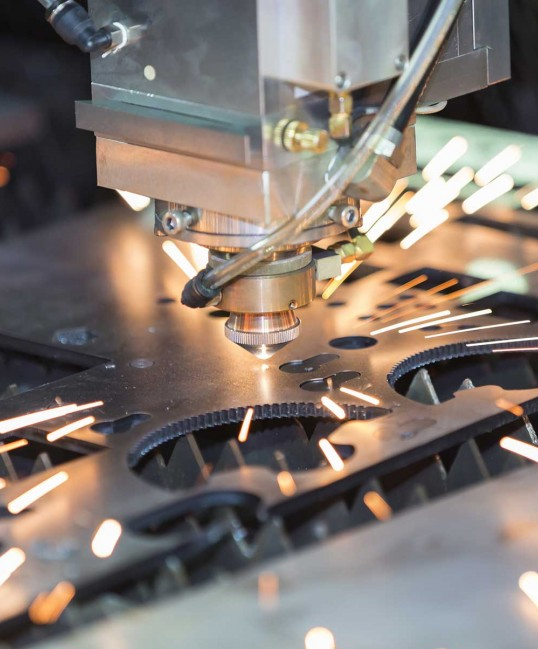

Manufacturing and businesses move fast these days – you can’t afford a sluggish response and delivery rate when you need parts. But you shouldn’t have to compromise on quality to get a fast turnaround, either. That’s where Questech comes in – high quality Ceramic Laser machining and drilling with one of the highest volume output shops in the world. Learn more about our experienced team and what we can do for you and your application.

With over 30 years of experience in the precision machining and drill area, we’re the experts that will perform for you.

Services We Provide

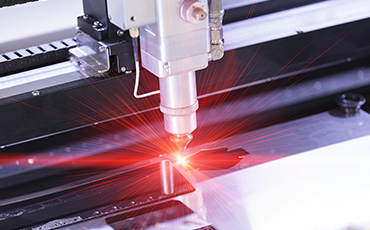

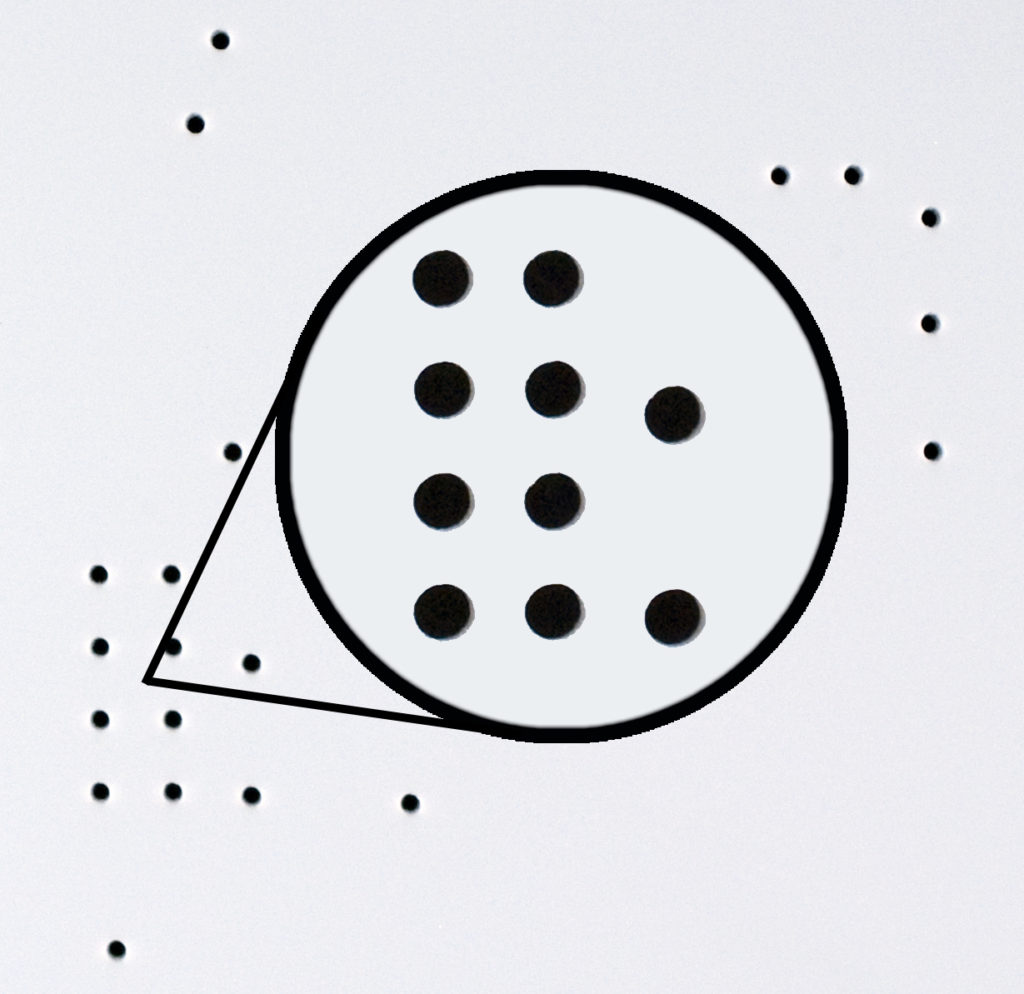

YAG Laser Services

YAG Laser Services at Questech are second to none. Multiple systems are in operation to handle critical geometry thin film..

CO2 Laser Services

Questech CO2 Laser Services utilize our in-house developed multi-beam heads to provide high throughput, while…

Diamond Sawing Services

With multiples of the latest ADT 7134 high speed diamond saws, Questech has become an industry leader in Diamond…

Our Products

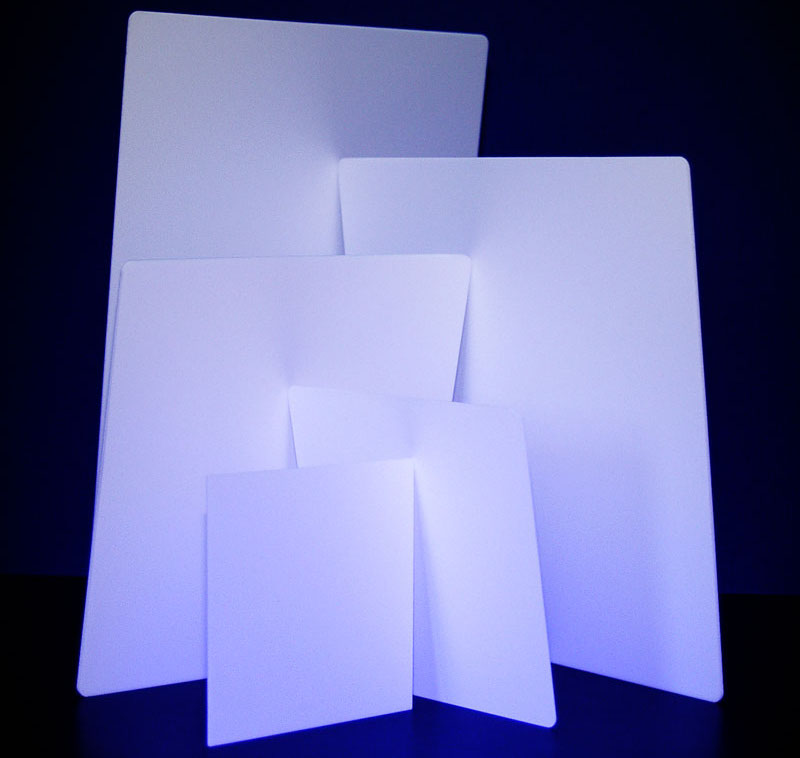

Technikote Advanced Surface

TECHNIKOTE is an advanced polymer formulation that provides superior protection to ceramics, plastics, metals, silicons and other high technology microelectronic materials during processing…

Ceramic Inventory

Questech maintains a wide variety of standard ceramic sizes and types in inventory from the major suppliers of opaque, 96% and 99% alumina substrates. Whether you require production…