CO2 Laser Machined Parts Tips & “Rules Of Thumb”

Removal of edges of customer supplied material requires at least .100 inch border (waste area).

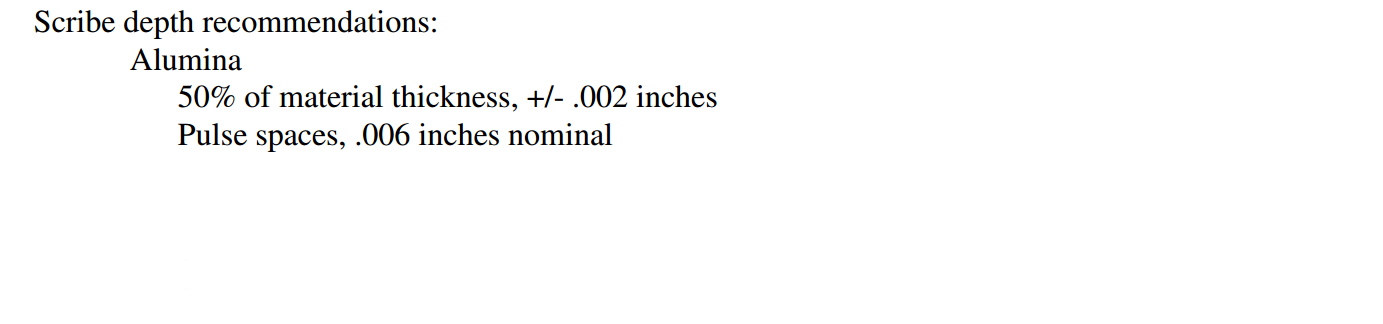

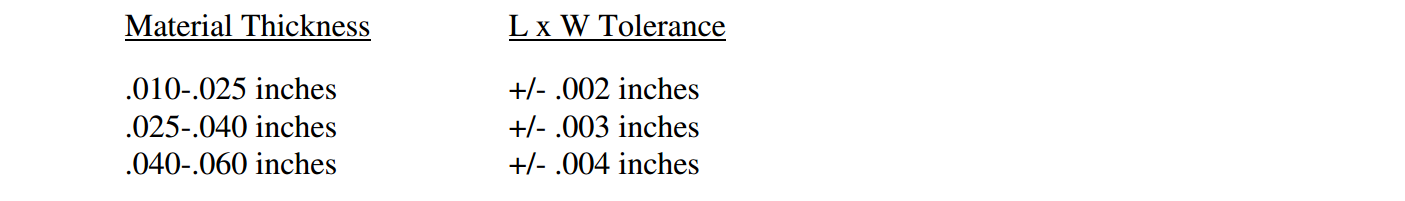

Tolerances for scribed and broken parts:

If using edges for critical pin alignment for printing, sawed edges or laser machined “flats” are recommended.

For “window frame” parts: Side wall thickness should be at least 2 times material thickness and outside of frames should be diamond sawed.

“Post cut” designs: allow .002 inches minimum space to metal feature.

Corner chamfer cuts inside saw alleys should be line cuts as opposed to triangular “drop outs”.

Electronic file formats:

AutoCAD .dwg is best

.dxf is acceptable

Drawings: Include all pattern to cut feature dimensions and tolerances to avoid order delays.

If holes must be drilled to fit pins, specify pin gage measurement requirement. If physical device must fit into cutout, specify device maximum size. Caution: allow for .002 inch typical corner radii when designing cut- outs.

Hole tolerances: +/- .002 inches diameter capability single side. Taper must be taken into account for two side tolerances.

Kiln firing (anneal) standard cycle: Ramp fire over 24 hour cycle to 2000 degrees F or 1093° C peak.

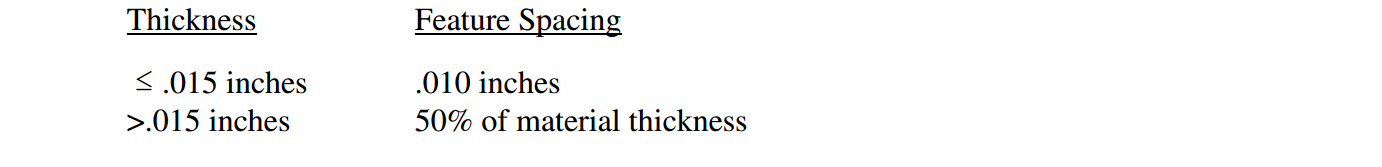

Feature spacing in alumina to avoid cracking:

If the part looks like it will fall apart from machining, it probably will.