Advantages

Aluminum nitride (ALN) offers advantages as a thermal management material while introducing significant laser machining challenges. Compared to other common microelectronic ceramic materials, aluminum nitride is very unforgiving of the stresses of CO2 LASER cutting.

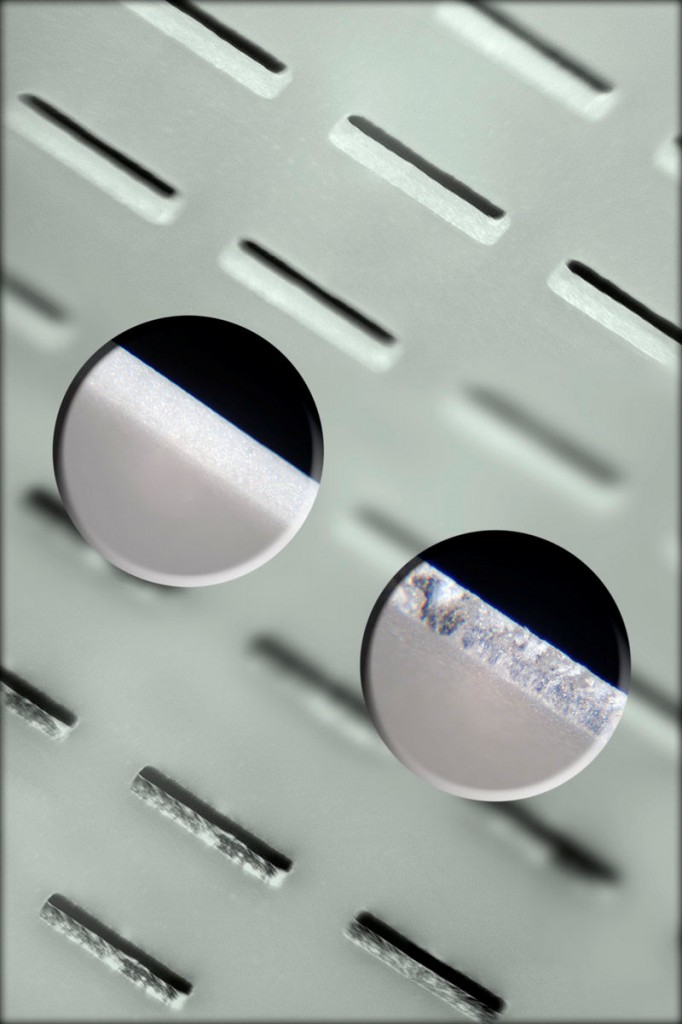

The primary challenges encountered are the creation of metallic aluminum particularly on the cut feature side walls, bulk material chip outs and more heat affected zone as compared to aluminum oxide of the same thickness. Questech Services has developed laser machining processes and post machining processes which ameliorate the problems. The proprietary processes developed attack the problems using several approaches. A careful selection of cutting assist gas coupled with CO2 LASER parameters along with special real time process control monitoring is necessary. Laser setup is more rigorous and time consuming. Generally, more material is consumed in process qualification than in processing aluminum oxide or beryllium oxide. More average laser power is required for cutting as compared to aluminum oxide so special attention must be paid to tooling and cooling as well as CO2 LASER parameters to eliminate micro-cracking problems.

The primary challenges encountered are the creation of metallic aluminum particularly on the cut feature side walls, bulk material chip outs and more heat affected zone as compared to aluminum oxide of the same thickness. Questech Services has developed laser machining processes and post machining processes which ameliorate the problems. The proprietary processes developed attack the problems using several approaches. A careful selection of cutting assist gas coupled with CO2 LASER parameters along with special real time process control monitoring is necessary. Laser setup is more rigorous and time consuming. Generally, more material is consumed in process qualification than in processing aluminum oxide or beryllium oxide. More average laser power is required for cutting as compared to aluminum oxide so special attention must be paid to tooling and cooling as well as CO2 LASER parameters to eliminate micro-cracking problems.

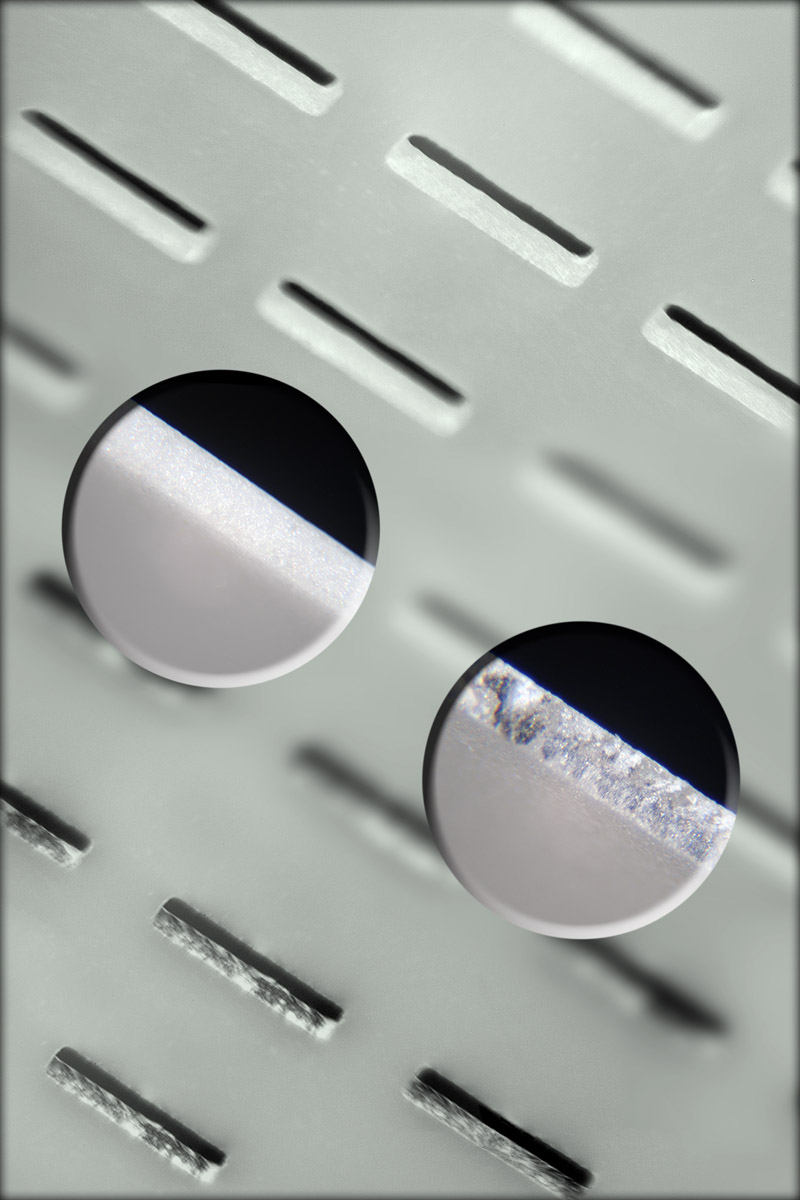

After the machining process is completed and the slag created by the cutting process is removed, the proprietary post laser machining processes of the completely machined and de-burred parts must be performed. These proprietary processes must remove any latent metallic aluminum material from the cut sidewalls and adjacent heat affected zone without any significant altering the material surface finish. The requirement that insignificant metallic material is allowable due to both thick and thin film substrate metallization requirements is the standard that Questech’s process technology reliably fulfills. Furthermore, the Questech process is able to cope with the material variation challenges from different aluminum nitride substrate manufacturers.

Summary of Aluminum Nitride Machining Advantages

The Questech production aluminum nitride machining process produces microelectronic substrates with the following properties:

- Tight tolerance, low taper cut features (via holes, cut outs, slots, contours)

- Clean, metal free cut side walls (critical for subsequent reliable metallization adhesion of vias and filled vias)

- Ultra low chip outs

- Ultra low heat affected zone

- Insignificant alteration of substrate surface finish

- Insignificant micro-cracking

- Diamond sawed edges as required

- Competitive pricing